Frequent Searches

Frequent Searches

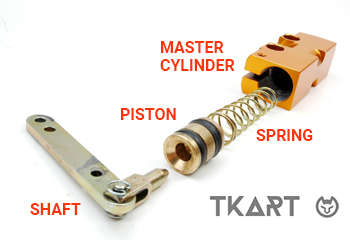

Master cylinder and piston. Apart from technological advances, evolutions, experiments, etc. these two accessories are always the indisputable protagonists of a kart’s braking system.

Over the years, many systems have been developed to make braking more powerful, reliable and versatile, but in any case the “basic” work of the master cylinder and piston is always the same. A job that, with the passage of time and wear, may not be as effective as in the beginning, with obvious repercussions on performance and safety. Brake system servicing is therefore an important and decisive, although not excessively complex operation (especially for brakes without stroke recovery, such as that used in this article), and which can allow you to “reset” one of the most important parts on a go-kart.

Let’s start with the master cylinder. Firstly, it is necessary to remove it from the chassis (for the master cylinder used by Dr. TKART you just have to unscrew two hexagon screws), disconnect the connector with the brake tube and, to work on it, remove the dust cover that covers it at the front.

Now the master cylinder is opened by unlocking the pin fastening the tie rod: in our case, the pin is blocked by a keyway, which must be unscrewed, but there may be other locking systems, such as, for example, a fastened shaft. Once the pin is unblocked so it can be removed, you have to be careful to hold the lever with your finger so that the thrust of the spring inside the master cylinder does not jump out of the piston. With the pin removed and having accompanied the lever until it is removed, the master cylinder is disassembled.

It is important to remember the sequence with which the various elements inside the master cylinder are positioned so that there are no surprises during the reassembly phase. Do not take this for granted, especially if it is the first time you are disassembling this accessory.