no results

Frequent Searches

"Axle"

"Tires"

"Setup"

"Caster"

"Seat"

"Carburetion"

"Carburettor"

Log in on TKART

Log in on TKART

Your likes show other users whether you liked the article.

Read all the contributions from the community and help enhance this article with your experience.

Login to continue

Login to continue

Frequent Searches

Exclusive Content

Exclusive Content

RIGHETTI RIDOLFI, YESTERDAY AND TODAY

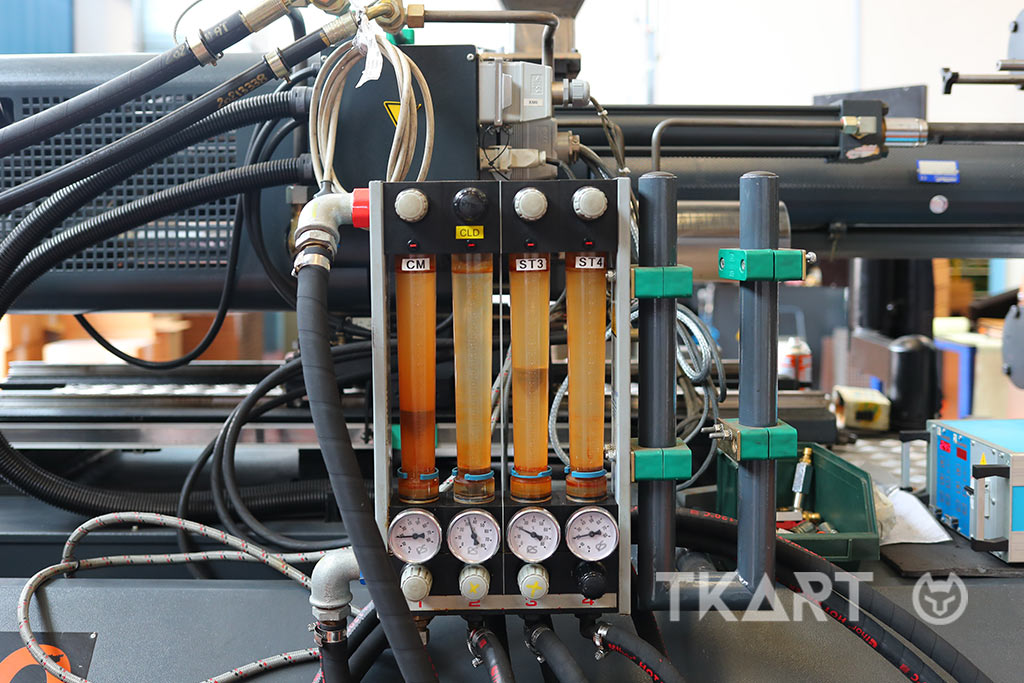

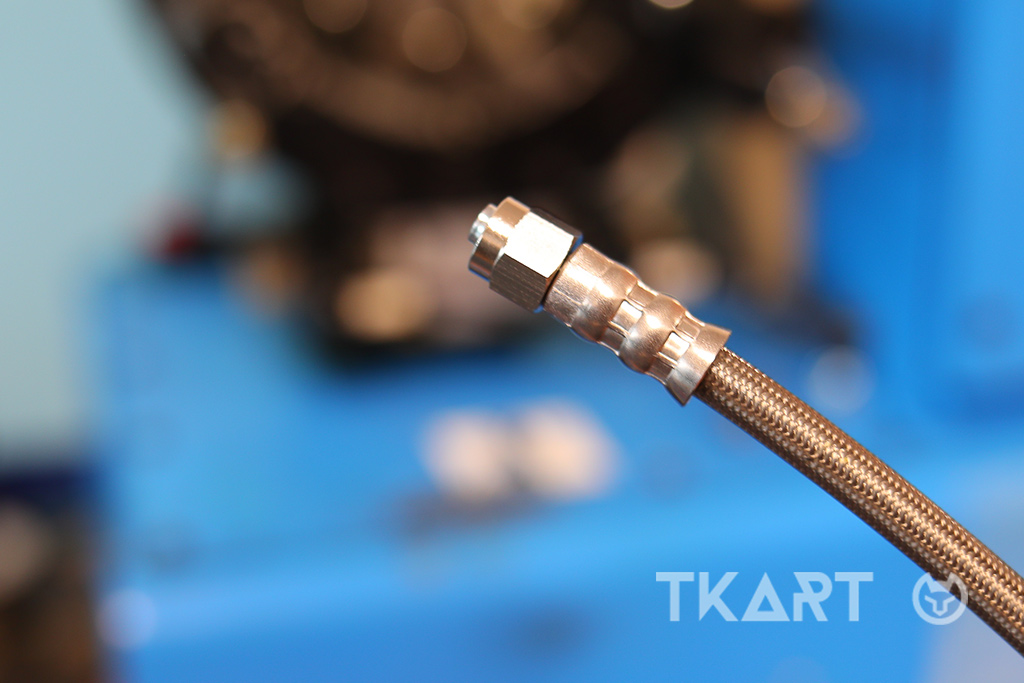

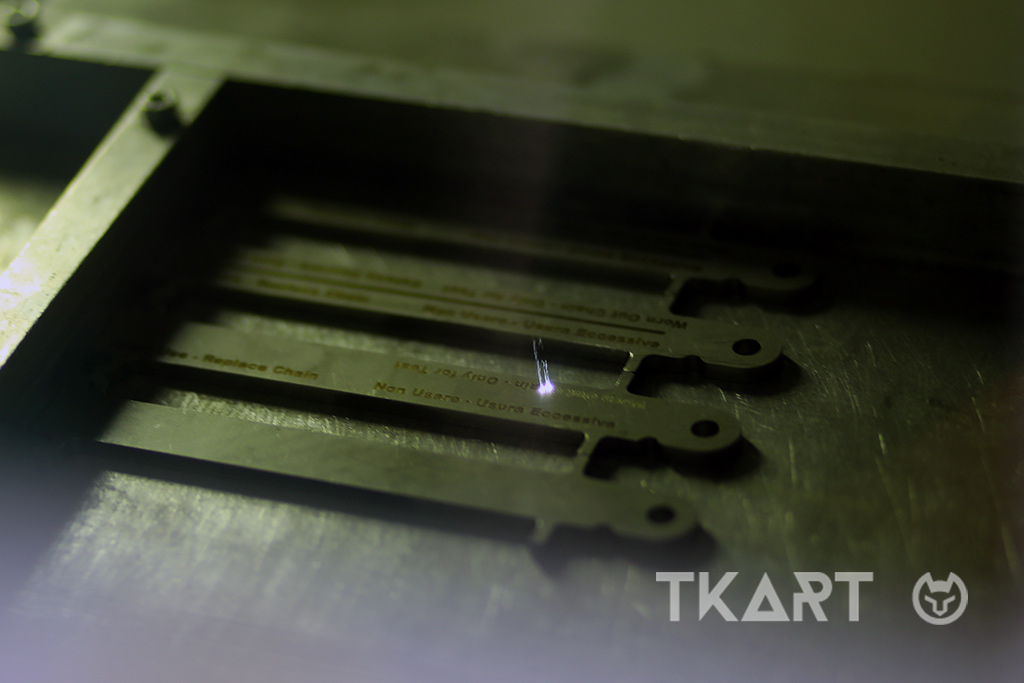

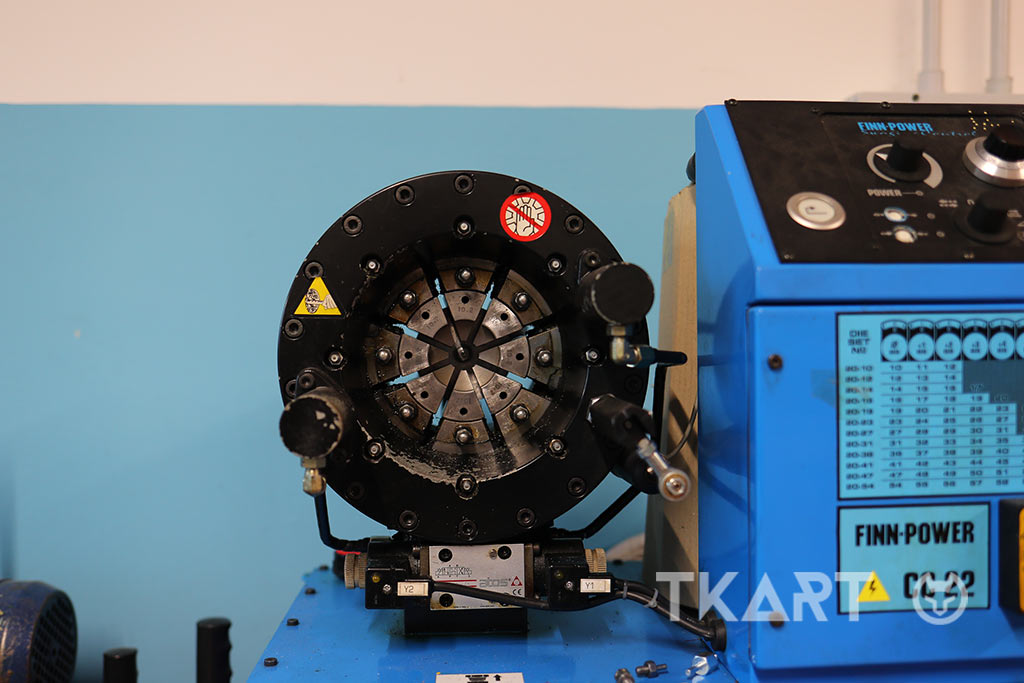

CHASSIS ASSEMBLY AND ACCESSORIES

PLASTIC MATERIAL DEPARTMENT