Frequent Searches

Frequent Searches

After a certain amount of use the piston needs to be replaced. Official teamsthat are constantlycommitted to competitive racing go through this operation after every single weekend of racing. Those who participate in competitions in a more relaxed manner can replace the piston every 2 or 3 events. Everyone else can do so once their engine performance begins to fall off markedly, which generally means after 5-10 full days of kart use.

Piston replacement itself is simple, as Dr. TKART has already demonstrated in this previous article.

What isn’t so simple is measuring the piston-piston ring-cylinder tolerance. Yet this is a key aspect for the correct functioning of any engine, and particularly the competitive two-stroke engine that karts utilize. Excessively high tolerances lead to losses of compression and, therefore, lower performance, especially at a low speed range. Tolerances that are too low, on the other hand, can compromise engine reliability, with seizures and the rupturing of the elastic piston ring.

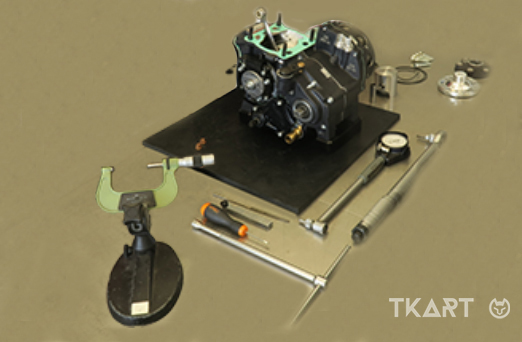

The first thing to do is remove the cylinder from the engine, followed by the piston from the connecting rod, by taking out the circular sealing ring from one of the two sides of the bore for the lower rod bearing.

Now we move on to the first measurement of tolerances. It’s true that we generally know the measurement of the old piston, but it may occur that a seizure has led to the lapping of the cylinder or even to grinding, and in these cases the measurements of the cylinder diameter will have changed significantly.

To obtain reliable measurements, it’s important to be sure that the cylinder and piston are at the same temperature, which needs to be in a range between 15 and 25 °C. 20 °C is ideal.

The ideal system for having the cylinder and piston at the same temperature would be to use a chamber at 20 °C,leaving all the components, including the measuring tools, inside it for 24 hours. A simpler and faster method, however, is to insert the piston inside the cylinder and leave the two parts coupled for a few minutes: the metal-on-metal contact provides optimal reciprocal heat transmission and in a short time (30 minutes) the components will have reached the same temperature.