Frequent Searches

Frequent Searches

Exclusive Content

Exclusive Content

WATER PUMP TRANSMISSION BELTS: HOW MUCH DO ASSEMBLY ERRORS AFFECT THE PERFORMANCE OF THE COOLING SYSTEM AND THE KART?

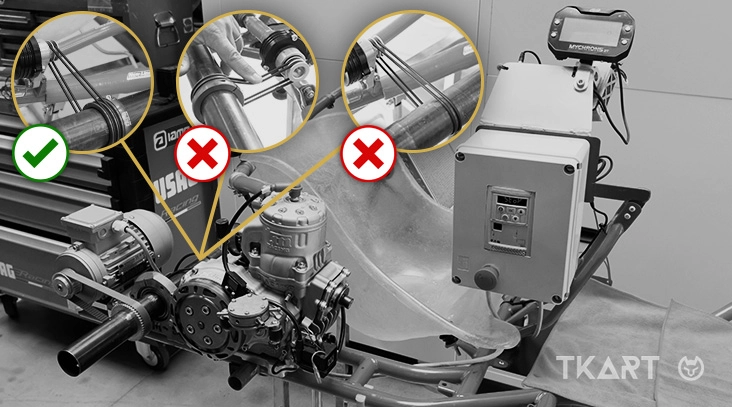

In liquid-cooled kart engines without an "on-board" water pump (i.e. not "incorporated" as part of the engine), the motion transmission system between the axle and the water pump plays a fundamental role in maintaining the optimal operating temperature for the operation of the engine (to learn more, read "Technique | Cylinder cooling" and "Technique | The radiator"). Therefore, it is of primary importance that all components of the transmission (pulley, water pump and drive belts) are mounted correctly. What happens when, on the other hand, due to inexperience, distraction or following some "paddock legend", the transmission system of the water pump is installed incorrectly? Thanks to the collaboration of New-Line Racing, we tested and measured with a special test bench the impact that the four most common installation errors have in terms of inefficiency of the cooling system or engine power absorption. And we found that every once in a while, the numbers... Lie. Or perhaps it's better to say that they are not complete!

Check the differences, in terms of water flow rate (from the radiator to the engine cylinder) and power consumption, generated by errors in the assembly of the water pump transmission.

With the support of New-Line Racing, we carried out five different bench tests:

New-Line Racing headquarters in Fiorano Modenese (Modena) - Italy

In order to have perfectly comparable situations, we did not carry out a real test on the track. We carried out bench tests instead, where the weather conditions were uniform and did not affect the results of the tests.