Frequent Searches

Log in on TKART

Log in on TKART

Your likes show other users whether you liked the article.

Read all the contributions from the community and help enhance this article with your experience.

Login to continue

Login to continue

Frequent Searches

Exclusive Content

Exclusive Content

GUIDE TO PURCHASING OTK KART GROUP RIMS (FOR TONY KART, KOSMIC KART, LN RACING KART, EXPRIT…)

A range of 7 products designed for Junior/Senior Racing karts (both Shifter and Direct-Drive), MINIs and also the Rental scene. We explain how the Italian company’s rims are produced, the construction decisions made by its R&D department and which model to choose based on the weather conditions and the grip out on the track.

THE COMPANY

OTK Kart Group – which includes the brands Tony Kart, Kosmic Kart, Exprit Kart, LN Racing Kart, Gillard Kart, EOS Kart, Redspeed Kart - is the leading manufacturer of chassis and components for Racing Karts (but also produces Rental karts, Viper Kart). As regards the production of rims, OTK Kart Group manages the design and manufacturing phases of its products entirely "in-house". The only parts delegated to external suppliers are the casting of the rough components and everything concerning the final treatment processes. However, both processes are carried out according to the design rules and production standards established by OTK Kart Group itself.

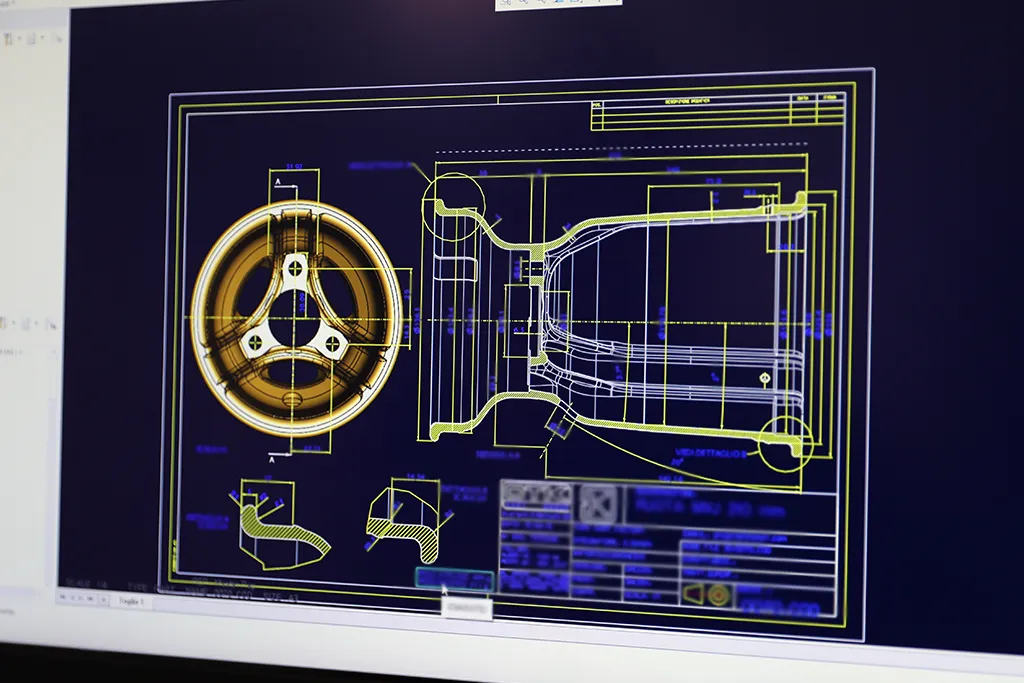

Design

The R&D department of OTK Kart Group designs every part of the karts it sells and, therefore, all rim models found in the price lists of the seven brands it possesses, led by Tony Kart. It always starts with finalizing the various projects (technical drawings) created using CAD (Computer-Aided Design) and "Creo" software in 2D and 3D, in order to evaluate different options that meet the needs of rim behavior and performance out on the kart track that the company has set out to achieve. Once the most convincing alternatives have been selected, there’s the production of prototypes using 3D printers. During this phase, both complete and (for magnesium models, which, unlike aluminum ones, have variable thicknesses) sectional prototypes are produced, in order to have an all-around vision of the various parts of the rim and be able to evaluate any modifications to improve the original projects. Once this preliminary development phase has been performed, there’s the production of the mold for the new rim model and the manufacture of a small batch of samples. This is followed by a test phase out on the track, which is crucial for monitoring the performance of the new products and checking that there are no problems related to their use that were not envisaged at the design stage. If the track tests show positive results, then there’s mass production of the new rim models, which are consequently officially added to the product catalog for the OTK Kart Parts line.

Casting

Based on the characteristics it wants the rim to have, but regardless of the material (magnesium or aluminum), the Italian company uses two distinct production processes:

The type of casting used directly influences the behavior of the rim out on the track. In fact, the rims produced by low pressure casting guarantee that the kart slides better in track conditions with hot asphalt and high grip. Those produced by die-casting, on the other hand, are optimal in conditions featuring cold tracks or ones that are not yet perfectly rubberized, as they guarantee the wheel assembly better road holding.

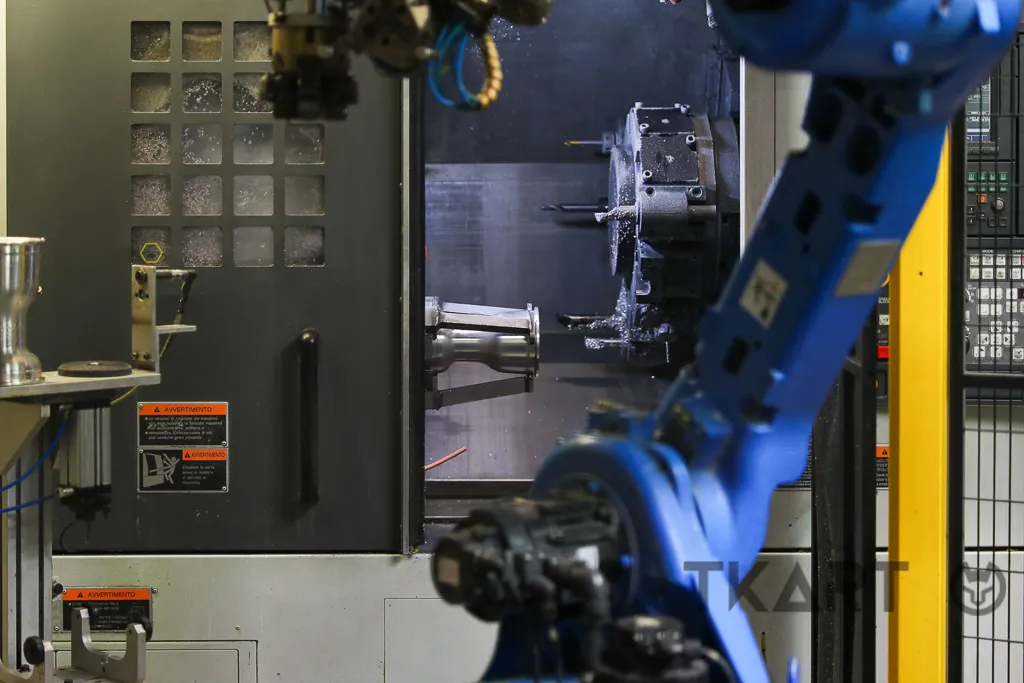

CNC machining

To guarantee the highest quality of its products, the Italian company uses technologically advanced machinery and has automated most of its production processes. Rims produced by low pressure casting require more CNC machining, as they have a lot of excess material. They are easily recognizable because they are processed both internally (meaning the area which is then covered by the tire) and externally (i.e. the part of the flange, meaning the part that’s visible when the tire is mounted). The last step for models produced using the low-pressure casting method is painting. In fact, this production methodology results in raw products that require more processing by robotic machinery. Every single rim made by die casting is checked by an operator and then processed externally, by means of robotic machinery, on the bead part of the tire. In terms of processing, die-cast rims are finished only on the edge since this production technique produces minimal excess material. Once this phase is completed, the rim is painted with a powder coating and is then placed back into the machine to carry out the work necessary to complete the product (such as, for example, centering the hub and making the holes for the anti-loosening screws).

Final treatments

The last production phase to which OTK Kart Group rims are subjected involves the treatments, which differ based on the casting method used and the construction material of the model.

This kind of treatment is not exclusive to aluminum rim models, however. Some magnesium rims, made using die casting, are also powder coated. The reason is also linked to maintaining temperature levels: these specific models are meant for use in cold track conditions, which therefore implies the need for more heat at a tire level.

Quality controls

Quality control, in the OTK Kart Group production cycle, doesn’t represent an actual phase that’s positioned before or after a specific process. It could be said that this task accompanies all the various steps in the construction of a rim, starting from the "initial" phase, i.e. the rigid checks and related quality tests that are carried out on the raw materials (aluminum and magnesium) purchased. Once a rim has completed all the steps in the production process, it is once again examined by the OTK Kart Group quality control department. Here, the engineers verify that each model conforms with certain safety and structural standards. The first step, to which all products are subjected, is the leak test: by immersing the rim in water, "putting it under pressure", it checks that no bubbles escape from the structure. In fact, the appearance of air bubbles indicates that there are cracks or damaged parts. The second step regards the analysis of eddy currents. This phase is carried out on a sample basis and represents a more in-depth test, which checks whether the rim has any micro-fractures or structural imperfections.

MEASUREMENTS TO KEEP AN EYE ON

The structure of the rim plays a very important role in track performance, which is why it’s important to pay attention to these measurements.

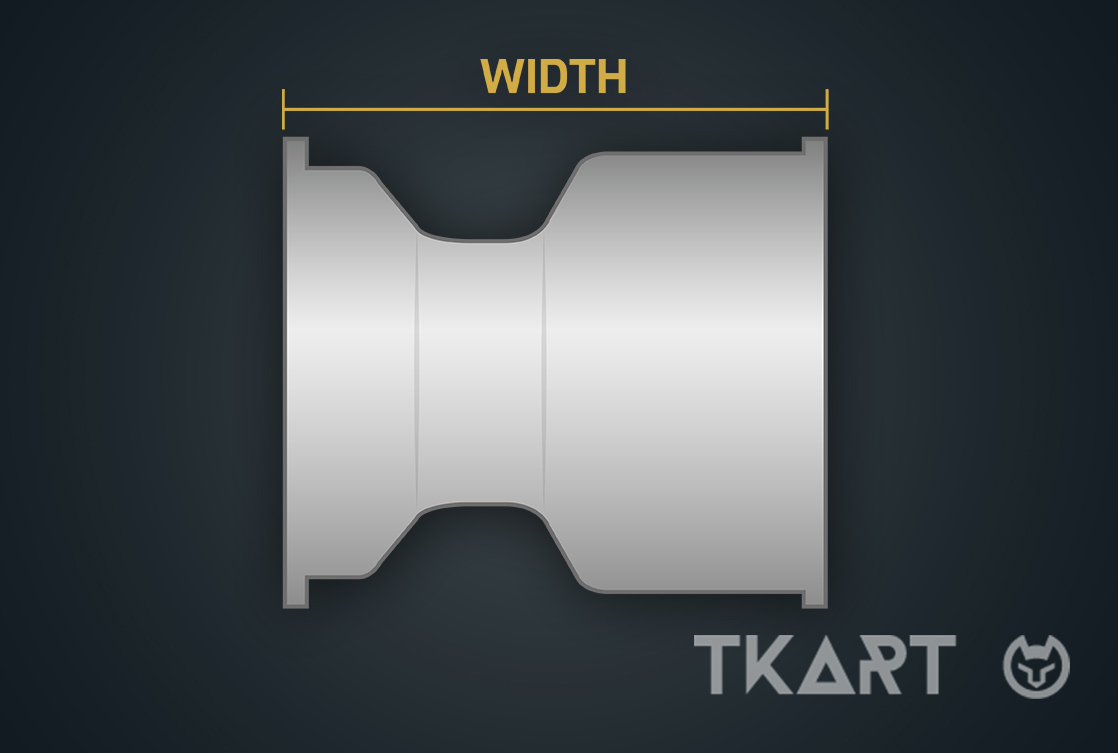

Width

By width, we mean the distance between the two profiles of the rim, internal and external. This measurement has maximum limits in CIK-FIA regulations: 135 mm for front dry rims and 215 mm for rear ones. However, as for wet rims the maximum measurements are 130 mm and 180 mm respectively (designed narrower, since a narrower tire "cuts through" the water more efficiently out on the track). These values are the same for all Junior and Senior chassis, corresponding to the following FIA Karting categories: OK, OKJ (Direct-Drive) and KZ (Shifter). As regards MINIs, the limits set are 120 mm at the front and 150 mm at the rear, valid for both dry and wet models.

For its part, the OTK Kart Group applies the following widths to its models:

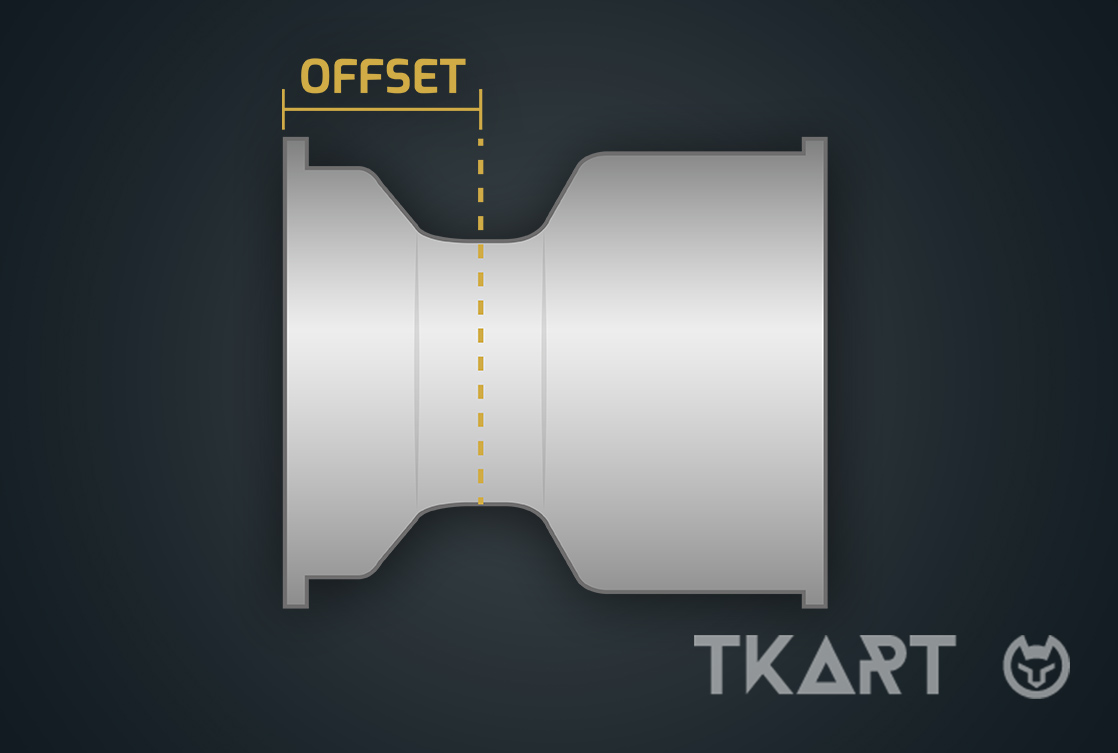

Offset

In the automotive sector, offset commonly means the distance (measured in millimeters) between the central plane of the rim and the plane where it is attached to the hub. In karting, however, it’s customary to define offset as the distance between the hub stop and the plane passing through the internal edge of the rim. This is a measure free from regulatory constraints and which is defined at the discretion of each individual manufacturer. This data, in fact, directly affects the torsional capacity of the wheel. To be clear, increasing the offset increases the rigidity of the wheel which, in turn, increases the level of grip that the kart will have on the track, especially when exiting bends. This is why it is customary to combine wheels with greater offsets to shifter karts (where the search for grip is generally preferred to smoothness, unlike direct drive classes) and to track situations with fairly low levels of grip. Despite this, OTK Kart Group has opted to standardize all its rims (Junior/Senior, MINI and Rental) with a front offset of 48 mm and a rear offset of 58 mm. That’s because these sizes adapt nest to the chassis of the brands that the Italian company owns (Tony Kart, Kosmic Kart, LN Racing Kart, Exprit Kart, Gillard Kart, Redspeed Kart and EOS Kart). In addition to that, the choice to standardize the offset measurement is based on the fact that the variation of this parameter can occur in terms of mm, measures which don’t guarantee significant changes in performance. Results can be achieved by working on many other aspects of correcting the flexibility and geometry of a chassis.

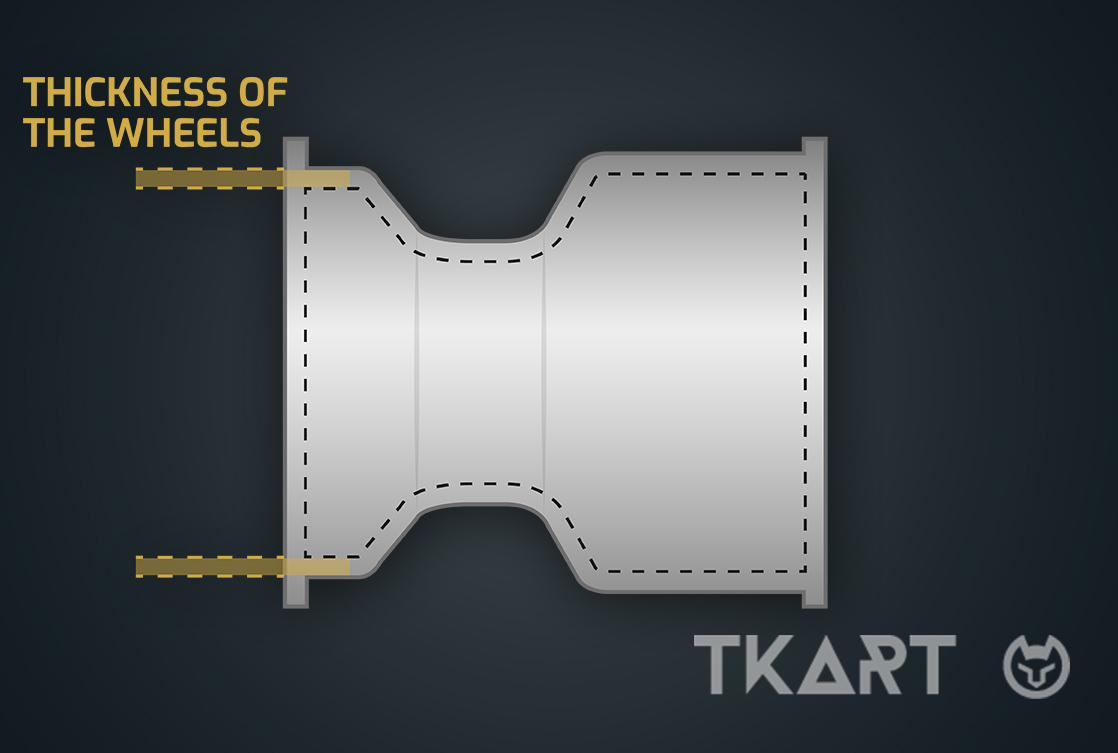

Thickness

This is the measurement, in millimetres, which expresses the thickness of the rim structure. Like the offset, FIA Karting regulations do not set any standards for this parameter, so each manufacturer can "play" on this aspect in order to give the rim a more or less rigid structure. In fact, when it comes to this part, OTK Kart Group rims have higher or lower values depending on the resistance or flexibility desired. Nevertheless, the measurement is always around 3 mm.

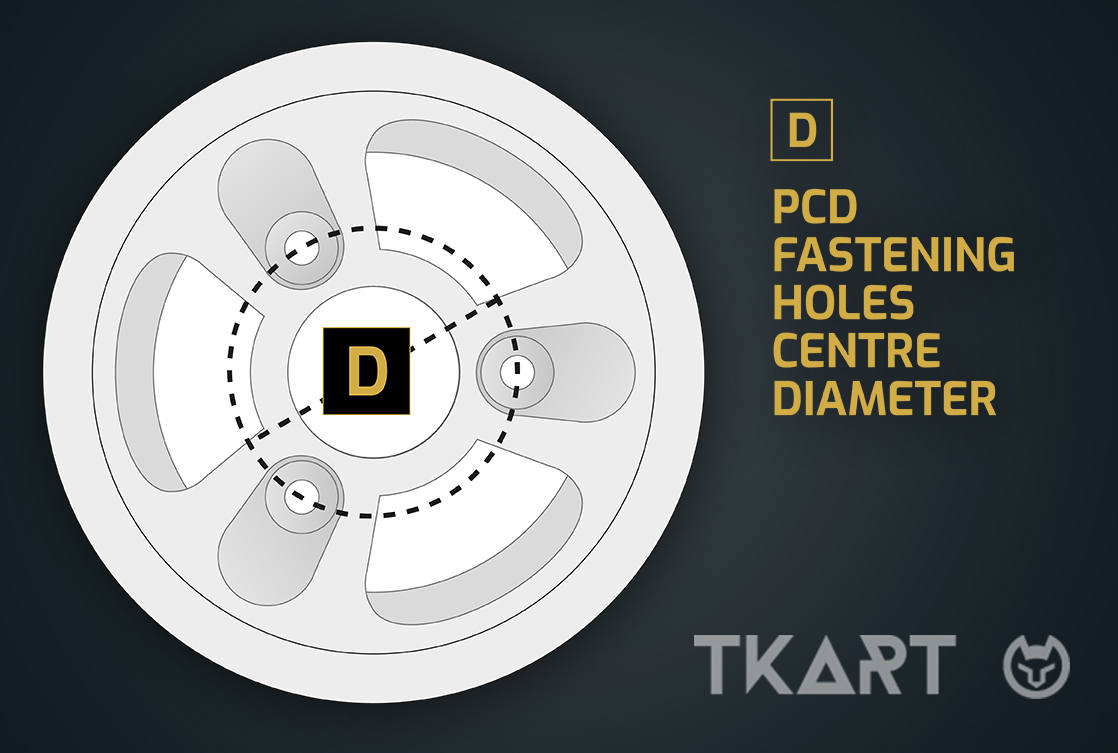

PCD

This means the diameter, measured in millimetres, of the hypothetical circumference created by joining the anchoring points of the rim to the hub. There are no regulatory restrictions here, either, but OTK standardizes the value for all models at 58 mm, the measurement that has always been used by the Italian company for its rims.

Utente che approccia per la prima volta il mondo del karting. Non ha mai avuto un kart proprio oppure lo possiede da pochi mesi. Gli mancano tutte le conoscenze di base ed elementari di questo sport e necessita di informazioni che gli permettano di orientarsi. Cerca risposte a domande come: come fare la miscela? Quali strumenti mi servono per gestire il kart? Quali sono le differenze tra la pressione di gonfiaggio delle gomme di un'auto e quelle di un kart? E come trasportare il kart in pista?

Utente che pratica il karting da più tempo, gestendo personalmente il proprio mezzo. Conosce le nozioni di base di questo sport, ma desidera rimanere aggiornato sulle novità del settore e ricevere consigli per migliorare le proprie capacità di meccanico e pilota. Cerca risposte a domande del tipo: come installare sistemi di raccolta dati e leggere le informazioni base? Come gestire al meglio le pressioni delle gomme? Come affinare il rapporto del kart per migliorare le prestazioni? Il praticante potrebbe rimanere tale per tutta la vita, preferendo non affrontare questioni tecniche troppo complesse, ma continuando a migliorarsi e divertirsi nel mondo del karting.

Si tratta di un utente praticante che non si accontenta delle conoscenze base di questo sport, ma vuole approfondire fino ai massimi livelli ogni singolo aspetto legato alla guida e alla tecnica. L’approccio è pressoché professionale. La discriminante è chiara: il praticante si ferma quando le attività relative al kart diventano complesse, come il cambio di un pistone o della candela, senza però cimentarsi in operazioni più avanzate come la lappatura della canna. L’esperto, invece, non si spaventa di affrontare questioni a complessità elevata, come per esempio equilibrare autonomamente l’albero motore o regolare l’anticipo.